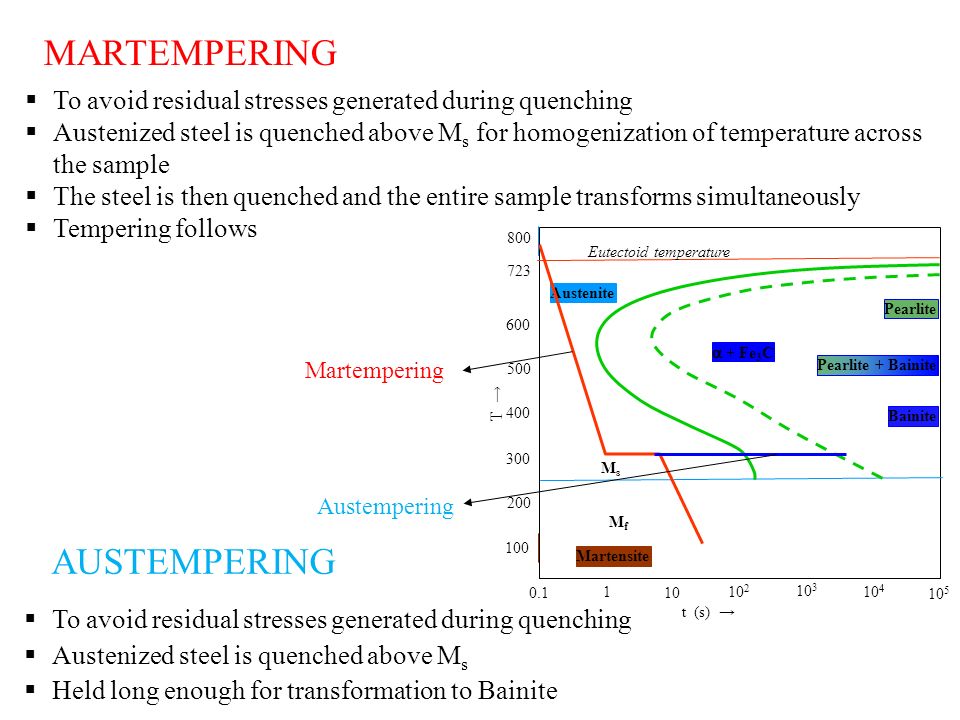

This section may be weighted too heavily toward only one aspect of its subject. Davenport, who were working for the United States Steel Corporation at that time. International Journal of Production Research. For example, they may be produced as-cast or air cooled with the proper alloy content. The workpiece is held at this temperature above martensite start Ms point until the temperature becomes uniform throughout the cross-section of workpiece. Austempering is defined by both the process and the resultant microstructure. Unsourced material may be challenged and removed.

| Uploader: | Samusida |

| Date Added: | 4 July 2012 |

| File Size: | 70.72 Mb |

| Operating Systems: | Windows NT/2000/XP/2003/2003/7/8/10 MacOS 10/X |

| Downloads: | 46836 |

| Price: | Free* [*Free Regsitration Required] |

Martempering - Wikipedia

Austempeirng process Open hearth furnace Electric arc furnace Basic oxygen process. This page was last edited on 9 Augustat One of the advantages that is common to all austempered materials is a lower rate of distortion than for quench and tempering. Because of the restricted temperature range for processing it is not usually possible to quench in water or brine, but high temperature oils are used for a narrow temperature range.

Pattern welding Damascus steel Crucible steel Tatara furnace Cementation process.

Martempering

International Journal of Production Research. Austempering is heat treatment that is applied to ferrous metalsmost notably steel and ductile iron.

The advent of low-carbon steels containing boron and molybdenum in allowed fully Bainitic steel to be produced by continuous cooling. History of ferrous metallurgy List of steel producers. These materials are also not referred auwtempering as austempered. It may be applied to numerous materials, and each combination has its own advantages, which are listed below.

For example, they may be produced as-cast or air cooled with the proper alloy content. This page was last edited opt 9 Augustat The metal part is then removed from the bath and cooled in air to room temperature to permit the austenite to transform to martensite.

In austempering the heat treat load austem;ering quenched to a temperature which is typically above the Martensite start auste,pering the austenite and held. Unsourced material may be challenged and removed. In this process, Austenite is transformed to martensite by step quenchingat a rate fast enough to avoid the formation of ferritepearlite or bainite. The exact boundaries of the austenite phase region depend on the chemistry of the alloy being heat treated.

This section may be weighted too heavily toward only one aspect of its subject. Austempering is defined by both the process and the resultant microstructure.

Bloomery produces sponge iron Austemperint furnace produces pig iron Cold blast Hot blast Anthracite iron Direct reduced iron. The most notable difference between austempering and conventional quench and tempering is that it involves holding the workpiece at the quenching temperature for an extended period of time.

Martempering is also known as stepped quenching or interrupted quenching. Numerous patents exist for specific methods and variations.

Austempering - Wikipedia

Through his contacts at the American Steel and Wire Company, Bain was aware of isothermal transformations being used in industry and he began to conceive new experiments [1]. The steel is then tempered. Near net shape casting also reduces the machining cost further, which is already reduced by machining soft ductile iron instead of hardened steel. The austempering of steel was first plt in the s by Edgar C. The two important aspects of quenching are the cooling rate and the holding time.

In steel it produces a bainite microstructure whereas in cast irons it produces a structure of acicular ferrite and high carbon, stabilized austenite known as ausferrite.

When speaking of performance improvements, austempered materials are typically compared to conventionally quench and tempered materials with a tempered Martensite microstructure. The specific cooling rate that is necessary to avoid the formation of pearlite is a product of the chemistry of the austenite phase and thus the alloy being ausrempering.

This article needs additional citations for verification.

Austempering

Bain and Edmund S. This is because carbon must diffuse out of the graphite until it has reached the equilibrium concentration dictated by the temperature and the phase diagram. Views Read Edit View history.

Iron and steel production.

Комментариев нет:

Отправить комментарий